1966 Ford F100 Wiring Diagrams are a crucial tool for anyone working on the electrical system of a 1966 Ford F100 truck. These diagrams provide a visual representation of the wiring layout, allowing mechanics and DIY enthusiasts to easily understand how the various components are connected and how electricity flows through the system.

Why are 1966 Ford F100 Wiring Diagrams essential?

1. Ensure proper installation: Wiring diagrams help ensure that all electrical components are connected correctly, preventing issues such as short circuits or malfunctioning parts.

2. Troubleshooting guide: When electrical problems arise, having a wiring diagram can help pinpoint the issue quickly and accurately, saving time and effort.

3. Restoration projects: For enthusiasts restoring a 1966 Ford F100, wiring diagrams are essential for maintaining the authenticity of the vehicle’s electrical system.

How to read and interpret 1966 Ford F100 Wiring Diagrams effectively

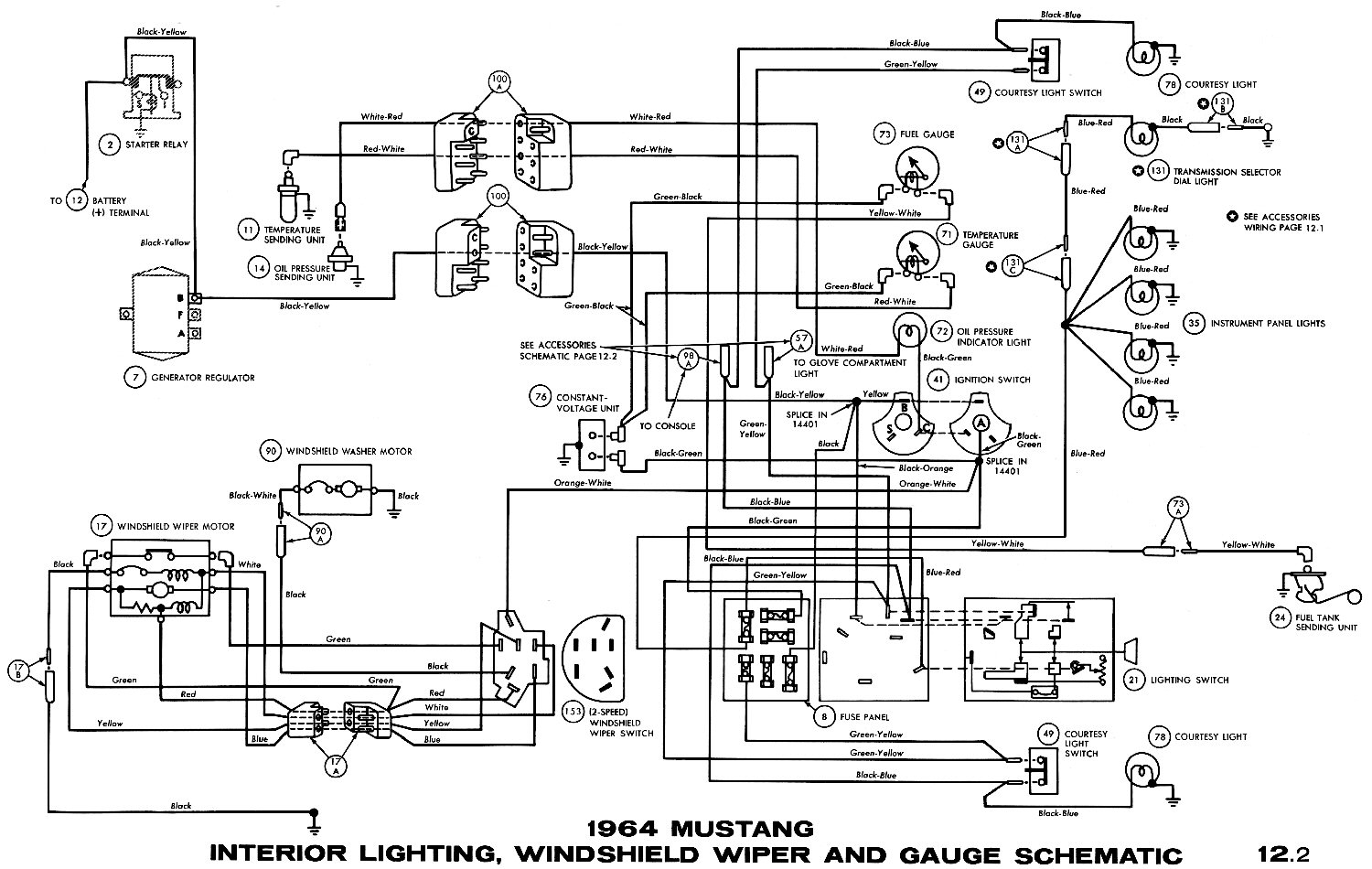

1. Understand the symbols: Familiarize yourself with the symbols and color codes used in the wiring diagram to identify different components and connections.

2. Follow the flow: Wiring diagrams typically show the flow of electricity from the battery to the various components. Follow the lines to trace the path of the electrical current.

- Color coding: Different colors are often used to differentiate between wires of different functions, making it easier to identify connections.

- Labels and legends: Refer to the key or legend provided with the wiring diagram to understand the meaning of each symbol or abbreviation used.

Using 1966 Ford F100 Wiring Diagrams for troubleshooting electrical problems

1. Identify the problem area: Start by locating the section of the wiring diagram that corresponds to the malfunctioning component or circuit.

2. Check connections: Use the wiring diagram to check for loose or faulty connections, broken wires, or damaged components that may be causing the issue.

- Testing continuity: Use a multimeter to test for continuity in wires and components to identify any breaks in the circuit.

- Compare with reference: Compare the actual wiring layout of the vehicle with the diagram to spot any discrepancies or incorrect connections.

Importance of safety when working with electrical systems

1. Always disconnect the battery before working on the electrical system to prevent the risk of electrical shock or short circuits.

2. Use insulated tools: When handling electrical components, use tools with insulated handles to reduce the risk of electric shock.

3. Work in a well-lit area: Proper lighting can help prevent mistakes and ensure that you can see what you are doing clearly.

- Seek professional help: If you are unsure about working with electrical systems or reading wiring diagrams, it is best to consult a professional mechanic.

- Follow safety guidelines: Adhere to safety precautions and best practices to protect yourself and prevent accidents when working with electrical systems.

1966 Ford F100 Wiring Diagram

1966 Ford F100 Electrical Diagram

1966 Ford F100 Wiring Diagram

1966 Ford F100 Engine Wiring Diagram

1966 F100 Wiring Diagram – Natureced

Wiring Diagram 1966 Ford F100 Collection – Faceitsalon.com

[DIAGRAM] 1966 Ford F100 Steering Column Wiring Diagram – MYDIAGRAM.ONLINE

![1966 Ford F100 Wiring Diagram [DIAGRAM] 1966 Ford F100 Steering Column Wiring Diagram - MYDIAGRAM.ONLINE](http://www.oldcarmanualproject.com/tOCMP/wiring/5765wiring diagrams/Ford/MWire5765-213.jpg)